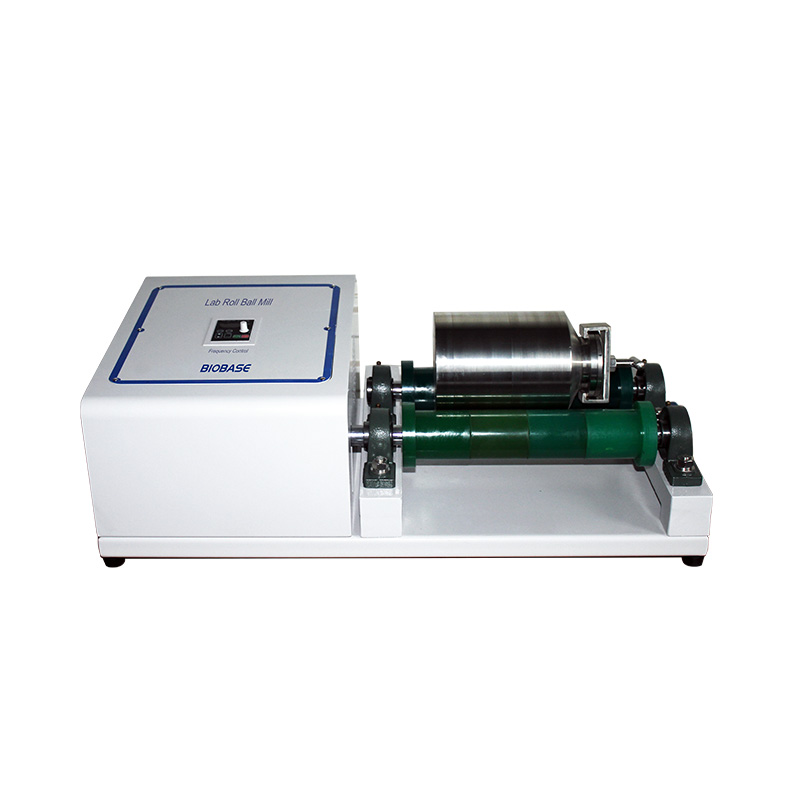

Laboratory Roller Ball Mill 0.5~15L

Brand BIOBASE

Product origin CHINA

Delivery time Within 7 days

Supply capacity Factory Direct Supply

Model BKBM-5 BKBM-15

Introduction:

When the laboratory roller ball mill is in operation, the grinding media and materials inside the cylinder are lifted to a certain height as the cylinder rotates. Due to gravity, they break away from the cylinder wall and fall along a parabolic path. The materials are pulverized under the impact of the grinding media and the friction and shearing effects generated by the rolling and sliding of the grinding media.

Download

Application:

The laboratory roller ball mill is a superfine grinding and mixing equipment for laboratories and small-batch production. It has an elegant and novel appearance, a compact structure, and is easy to operate. It features high work efficiency and uniform fine particle size, making it a preferred device for scientific research, teaching, experiments, and production. It can be widely used in industries such as electronic materials, magnetic materials, ceramic slurries, non-metallic minerals, metal minerals, and new materials.

Features:

1. The machine has a compact structure and is easy to operate.

2. It features high work efficiency and uniform grinding particle size.

3. By adjusting the moving roller, grinding jars with different outer diameters within a certain range can be used.

4. Jar replacement is convenient, and both dry and wet grinding are uniform.

Technical Parameters:

Model | BKBM-5 | BKBM-15 | |

Capacity | 0.5~5L | 0.5~15L | |

Pot Quantity | 1 | 1 | |

Spindle Speed Range | 60~570rpm±10 | ||

Effective Length of Roller Shaft | 260mm | 340mm | |

Adjustable Distance Between Roller Shafts | 120mm | 140mm | |

Single Station Distance | 260mm | 340mm | |

Maximum Load per Tank | 35kg | 80kg | |

Maximum Roller Speed | 570rpm | ||

Optional Accessory | Ball Mill Tank | Roller stainless steel ball mill tank, roller corundum ball mill tank, roller nylon ball mill tank, roller polytetrafluoroethylene(ptfe) ball mill tank | |

Grinding Ball | Stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, cemented carbide balls, silicon nitride balls, high wear-resistant steel balls, manganese steel balls, nylon balls, cemented carbide, glass and other special metal materials | ||

Consumption | 0.4KW | 0.75KW | |

Power Supply | AC220V, 50/60Hz(Standard); AC110V, 50/60Hz(Optional) | ||

External Size(W*H*D) | 730*415*260mm | 845*435*270mm | |

Package Size(W*H*D) | 750*450*300mm | 850*450*300mm | |

Net Weight | 32kg | 43kg | |

Gross Weight | 45kg | 60kg | |

Note: Both the pots and balls are optional. Their materials are selected according to the customer's materials and requirements. The loadable material is 1/3 of the volume capacity, multiply the volume of the loadable material by the bulk density of the material to get the weight of the loadable material. | |||