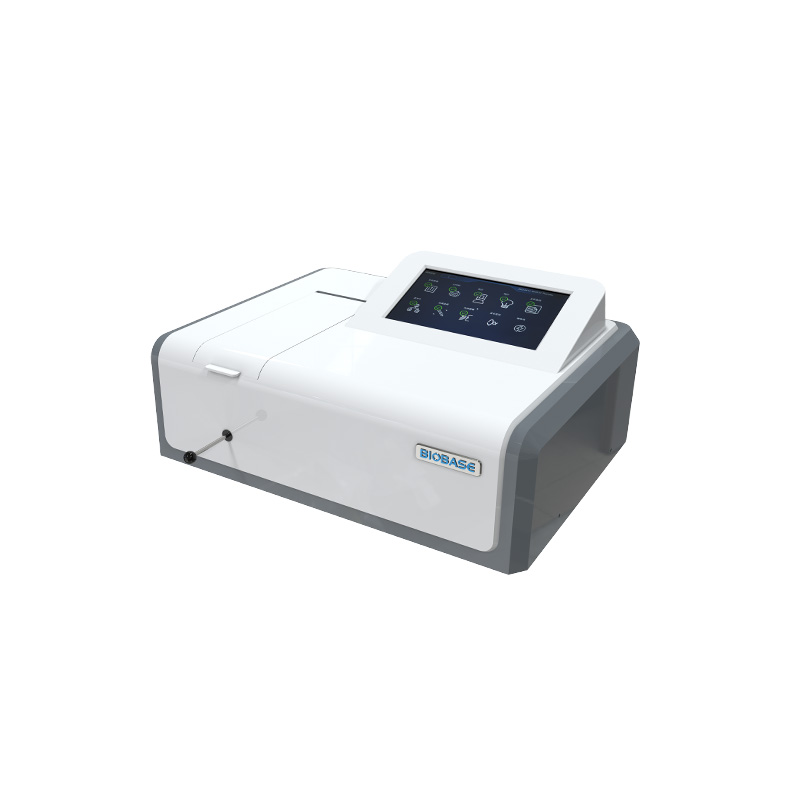

Atomic Absorption Spectrophotometer BK-AA220AES

Brand BIOBASE

Product origin CHINA

Delivery time Within 7 days

Supply capacity Factory Direct Supply

Model BK-AA220AES

Introduction:

BK-AA220AES flame graphite furnace integrated atomic absorption spectrophotometer, as an important precision instrument for metal analysis, has many advantages such as good selectivity, wide application range, high sensitivity, simple and fast operation, low analysis cost and high accuracy. It was widely used in industrial and livelihood fields such as geology, mining, metallurgy, agriculture, forestry, soil and fertilizer, hydrology and environmental protection, petrochemical industry, and third-party testing.

Download

Features:

1. The flame and graphite furnace analysis device is fully automatic switching, convenient for time-saving, one click in place.

2. The flame system adopts high-reliability flow control and has automatic control such as automatic ignition.

3. Graphite furnace system built-in multiple temperature control protection system, using double air circuit breaker and other design methods, effectively preventing current overload or abnormal temperature rise.

4. Equipped with a reliable gas-liquid separation system, gas filter, and other accessories to ensure the working condition of the instrument when the ambient humidity is high and the gas source is limited.

5. Equipped with multiple safety interlocking devices and prompt information protection functions, the instrument has an automatic power outage, alarm prompts protection in case of abnormal situations involving safety.

6. The instrument features a modular design for easy customer replacement or repair.

7. The instrument supports functional extensions such as hydride method.

Technical Parameters:

Model | BK-AA220AES |

Wavelength Range | 170~900nm |

Spectral Bandwidth | 0.1, 0.2, 0.4, 1.6nm |

Wavelength Accuracy | ≤±0.1nm |

Wavelength Repeatability | ≤0.05nm |

Detector | Photomultiplier tube detector |

Baseline Stability | Drift ≤0.002Abs, noise ≤0.001Abs(Steady 30min) Drift ≤0.002Abs, noise ≤0.001Abs(Dynamic 15min) |

Resolution | Spectral bandwidth deviation ≤0.02nm Manganese double line valley to peak energy ratio ≤25% |

Characteristic Concentration/Content | Flame method for Cu: ≤0.025μg/mL/1% Graphite furnace method for Cd: ≤0.5pg |

Detection Limit | Flame method for Cu: ≤0.002μg/mL Graphite furnace method for Cd: ≤0.4pg |

Preciseness | Flame method for Cu: ≤0.3% Graphite furnace method for Cd: ≤2.0% |

Background Correction Ability | Deuterium lamp calibration 1.0Abs, background ≥90 times Self-absorption method correction 2.0Abs, background ≥90 times |

Diffraction Grating | Groove 1800lines/mm, blaze wavelength 250nm |

Lamp Stand | 8(Support simultaneous preheating of 1~4 lights) |

Standard Accessory | Element lamp(Cu*1, Cd*1, Hg*1), software working station |

Optional Accessory | Wide slit combustion head, adjustable nebulizer, hydride vapor generator, audit trailing software, oil-free air compressor, recirculating cooling water system, computer, printer, autosampler, oxygen-enriched high-temperature flame |

Power Supply | AC220V, 50Hz |

External Size(W*D*H) | Main unit: 1020*530*500mm GF power supply: 350*530*430mm |

Package Size(W*D*H) | Main unit: 1280*750*830mm GF power supply: 610*670*810mm |

Net Weight | Main unit: 85kg GF power supply: 32kg |

Gross Weight | Main unit: 160kg GF power supply: 70kg |

Flame System

Air-acetylene Burner | 100mm all-titanium burner |

Atomization Chamber System | Integrally molded from polyphenylene sulfide |

Burner System | Burner head height and horizontal position automatic adjustment, with burner angle rotatable |

Gas Flow Control System | Automatic ignition/fame-out |

Safety System | Emergency shutdown protection switch, automatic gas cut-off/shutdown/alarm in case of abnormal status, abnormal air pressure, ignition failure, gas leakage, abnormal flow rate, etc. |

Graphite Furnace System

Temp. Control Mode | Optical and constant voltage |

Heating Mode | Slope and stepped temperature programming |

Temp. Range | RT~3000℃ |

Heating Rate | ≥3000℃/s |

Precision Error | ≤1% |

Graphite Tube Type | Straight, platform, concave type |

Water&Gas Control Monitoring System | Inner gas, external gas and make up gas are controlled separately. Circulating water and gas flows monitoring system is equipped |

Safety System | Graphite furnace cut-off high current protection switch, automatic pause/cooling/alarm in case of abnormal furnace state/water and gas circuit control failure/graphite tube problem/temperature control failure, etc. |

Software Working Station

Smart Optimization | One-key operation for instrument optimization, supporting multi-task analysis |

Repeat Measurement | 1~99 replicates with auto-calculation of mean/SD/RSD |

Print/Export Reports | Word/Excel supported |

Auto-Calibration | Curve fitting, re-slope&concentration calculation, incl. standard addition method |