What are the biosafety cabinet classes?

There are multiple biological safety cabinet classes. But what are they and how are they different? Biological safety cabinet classes (or biosafety cabinet classes) are categories describing how the cabinet works and what it protects. These “categories” are Class I, Class II and Class III.

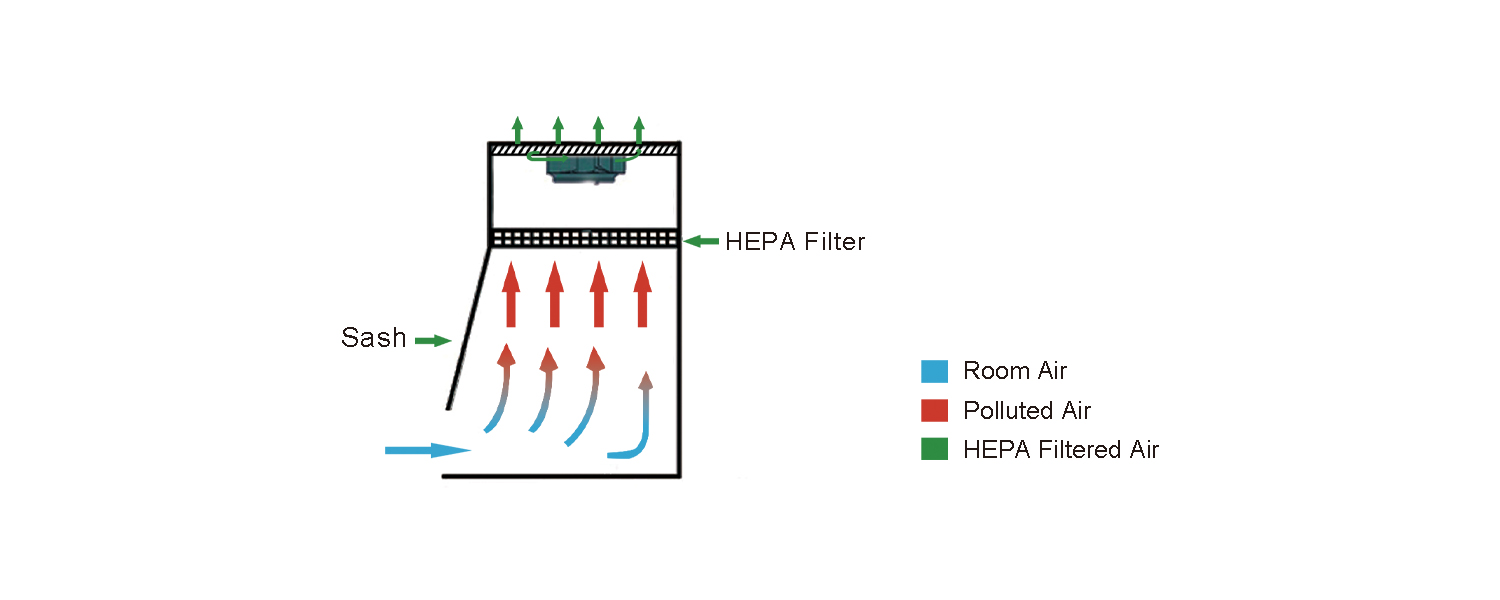

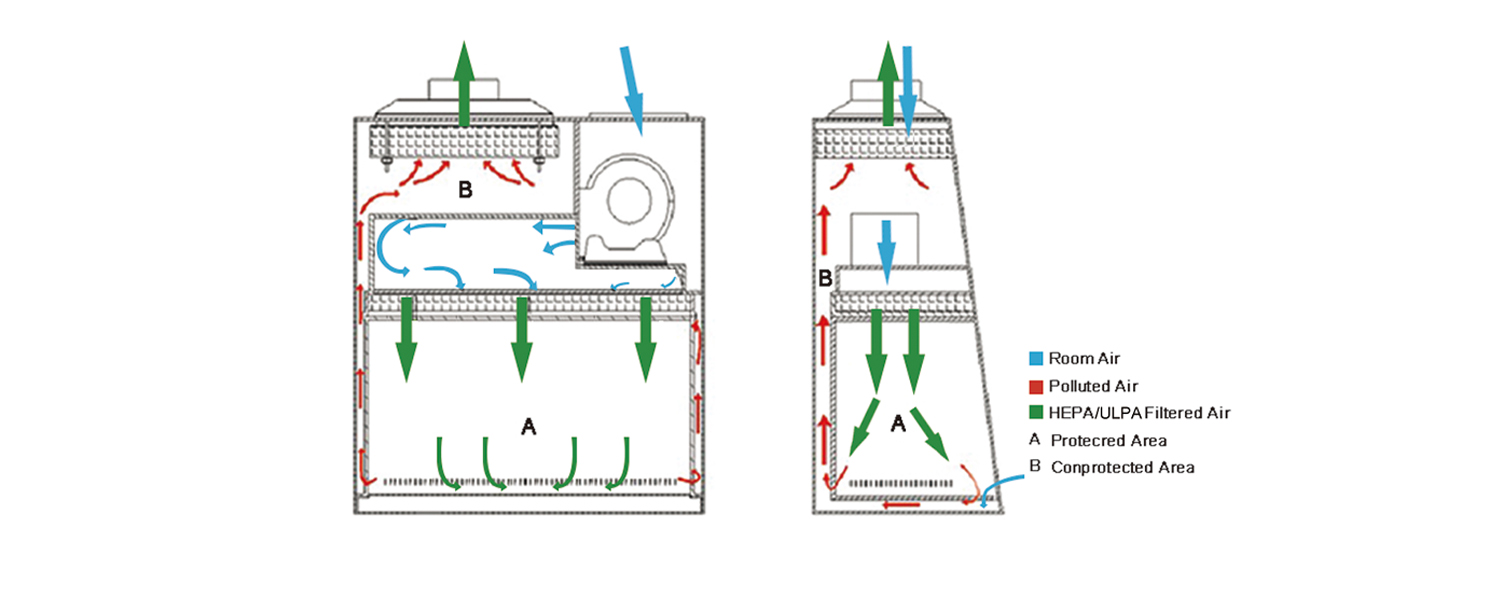

Class I

A Class I cabinet is defined as a ventilated cabinet for personnel and environmental protection. Class I cabinets do not offer product protection from contamination, significantly limiting their applications. They use unrecirculated airflow away from the operator. Class I cabinets have a similar airflow pattern to a fume hood but they also have a HEPA filter at the exhaust outlet. They may or may not be ducted outside. Class I cabinets are safe for use with agents requiring Biosafety Level 1, 2 or 3 containment.

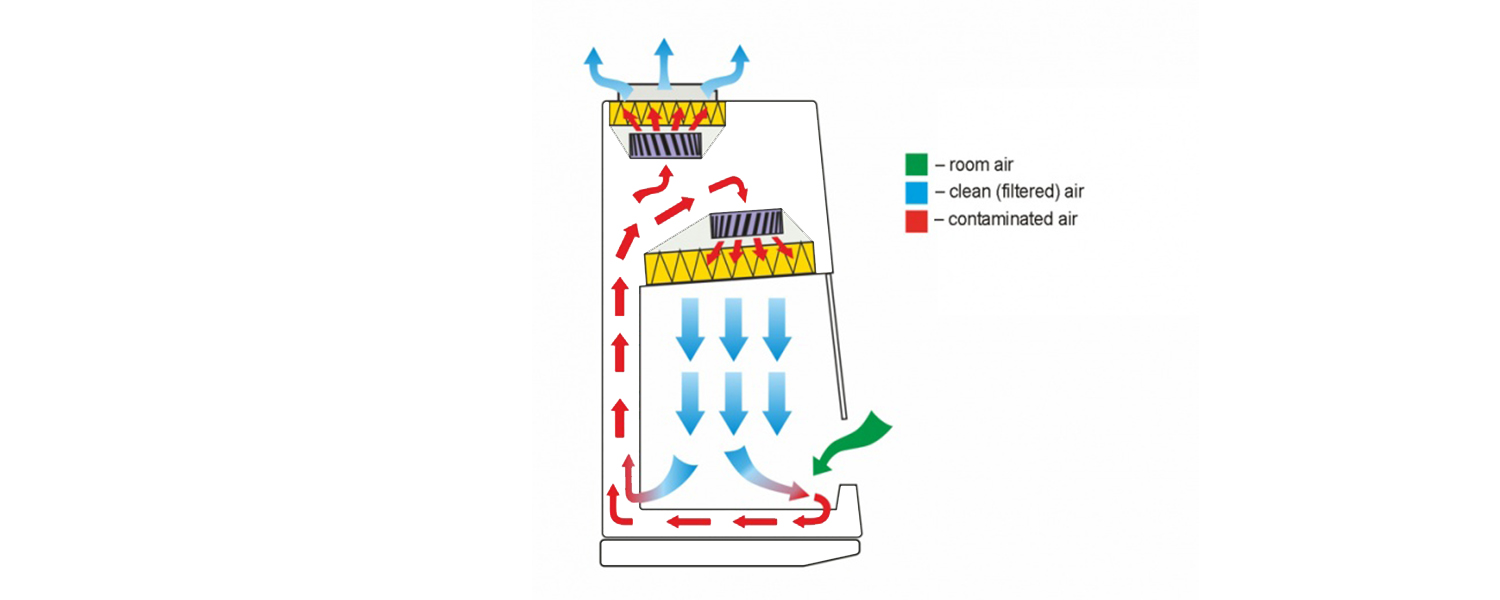

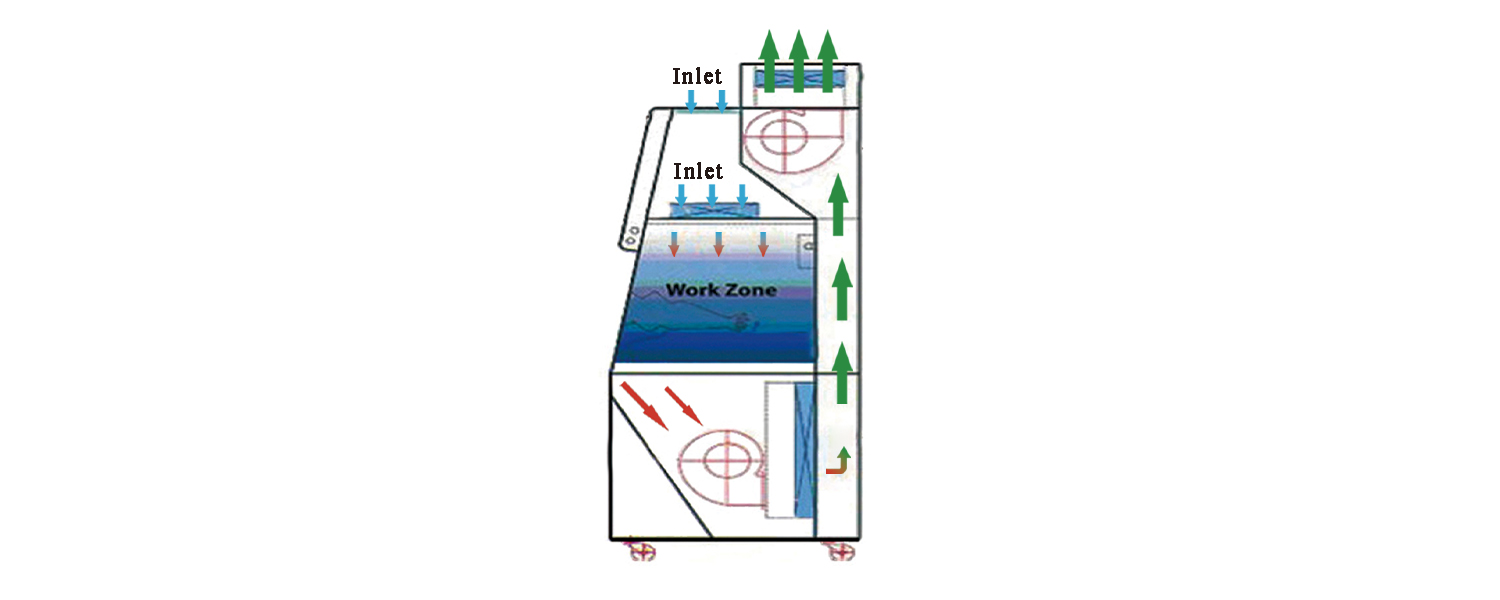

Class II

A Class II cabinet is defined as a ventilated cabinet for personnel, product and environmental protection for microbiological work or sterile pharmacy compounding. Class II BSCs are designed with an open front with inward airflow (personnel protection), downward HEPA-filtered laminar airflow (product protection) and HEPA-filtered exhaust air (environmental protection). These cabinets are further differentiated by types based on construction, airflow and exhaust systems. The types include A1, A2, B1, B2 and C1. They require all biologically contaminated ducts and plenums to be under negative pressure or surrounded by negative pressure ducts and plenums. Type B2 cabinets take this a step further, requiring all biologically contaminated ducts and plenums to be under negative pressure or surrounded by directly exhausted negative pressure ducts and plenums. Like Class I cabinets, Class II cabinets are safe for work using agents requiring Biosafety Level 1, 2 or 3 containment.

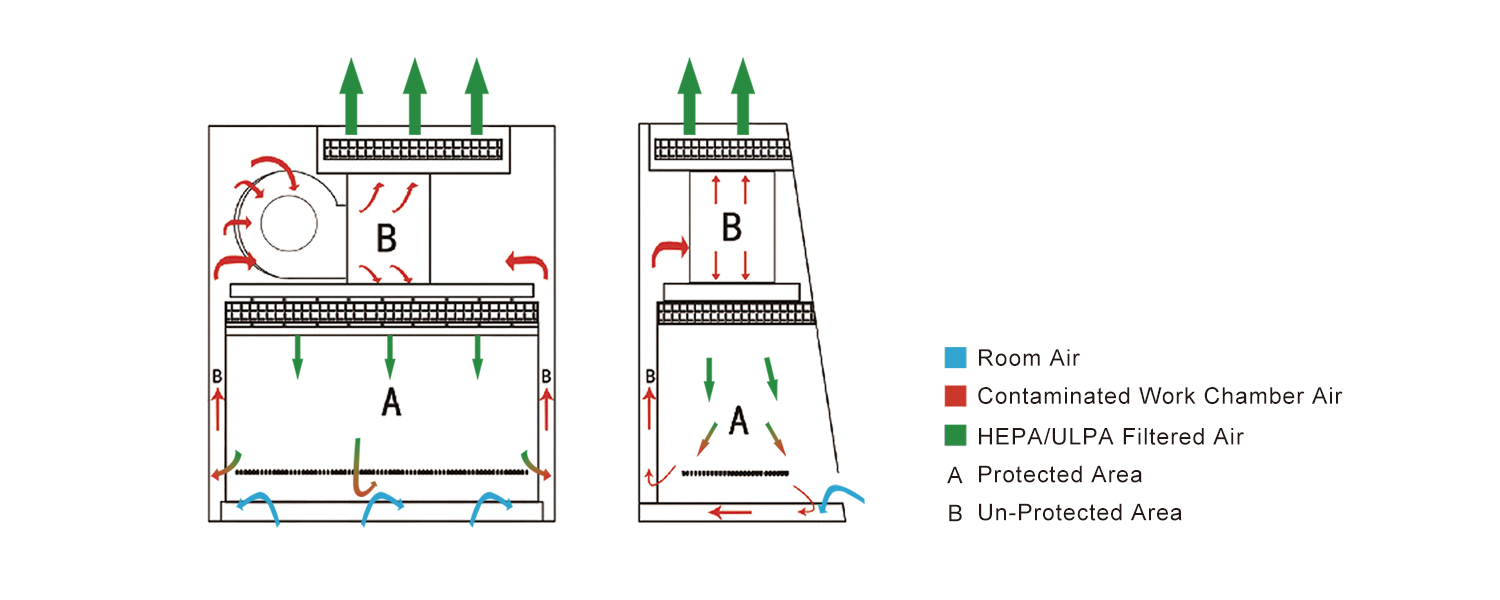

Type A1

A Class II, Type A1 cabinet must maintain a minimum average inflow velocity of 75 fpm through the sash opening. They may exhaust HEPA-filtered air back into the lab, or may be exhaust outside using a canopy connection. They are suitable for work using biological agents without volatile toxic chemicals and volatile radionuclides, but not for sterile hazardous pharmacy compounding.

Type A2

A Class II, Type A2 cabinet must maintain a minimum average inflow velocity of 100 fpm through the sash opening. Like Type A1 cabinets, they may exhaust HEPA-filtered air back into the laboratory, or may be exhausted outside using a canopy connection. Type A2 cabinets with a canopy connection are safe for work involving biological agents treated with minute quantities of hazardous chemicals. They may also be used with tracer quantities of radionuclides that won’t interfere with the work if recirculated in the downflow air.

Type B1

A Class II, Type B1 cabinet must maintain a minimum average inflow velocity of 100 fpm through the sash opening. They have HEPA-filtered downflow air composed mostly of uncontaminated recirculated inflow air and exhaust most of the contaminated downflow air through a dedicated duct that exhausts outside after passing through a HEPA filter. Similar to Type A2 cabinets, Type B1 cabinets are safe for work involving agents treated with minute quantities of toxic chemicals and tracer amounts of radionuclides if the chemicals or radionuclides won’t interfere with the work if recirculated in the downflow air. Unlike a Type A2, a Type B1 cabinet is also suitable for work involving minute quantities of toxic chemicals and tracer amounts of radionuclides required as an adjunct to microbiology applications as long as the work is done in the directly exhausted rear portion of the cabinet (this portion is not marked and therefore ever-changing as the airflow pattern adjusts with the loading of the cabinet’s HEPA filters).

Type B2

A Class II, Type B2 cabinet must maintain a minimum average inflow velocity of 100 fpm through the sash opening. They have HEPA-filtered downflow air drawn from the lab or the outside air (not recirculated from the cabinet exhaust) and exhaust all inflow and downflow air to the atmosphere after filtration through a HEPA filter without recirculation in the cabinet or return to the lab. Because of this, they are sometimes referred to as 100% Exhaust or Total Exhaust cabinets. Type B2 cabinets are suitable for work involving biological agents treated with hazardous chemicals and radionuclides required as an adjunct to microbiology applications.

Type C1

A Class II, Type C1 cabinet must maintain a minimum average inflow velocity of 105 fpm through the sash opening. Type C1 cabinets are unique in that they can operate as either a Type A cabinet when in recirculating mode or a Type B cabinet when exhausting. C1 cabinets can be quickly changed from one mode to the other by connecting or disconnecting the exhaust and having the cabinet recertified. The Type C1 also features a marked work area with clearly delineated spaces for storage and a work area with dedicated direct exhaust for use with hazardous vapors or radionuclides.

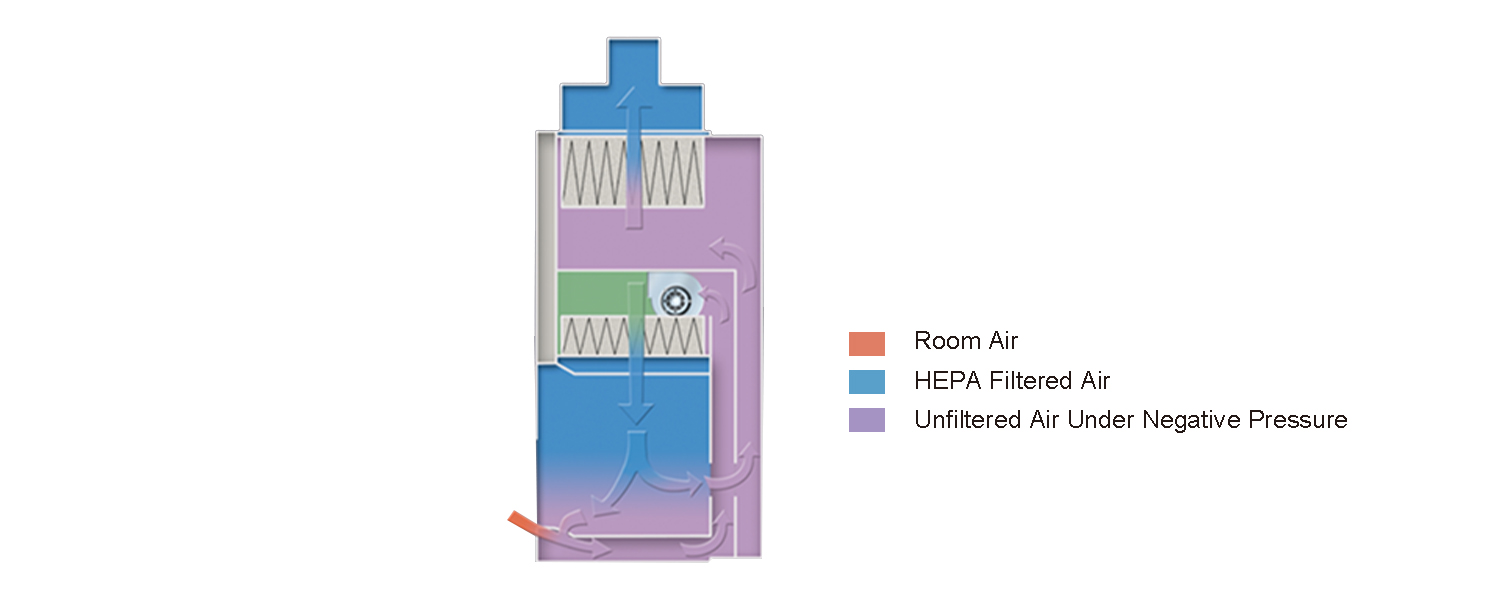

Class III

A Class III cabinet is defined as a totally enclosed, ventilated cabinet with leak-tight construction and attached rubber gloves for performing operations in the cabinet. Class III biosafety cabinets are also called glove boxes. The cabinet has a transfer chamber that allows for sterilizing materials before they leave the glove box. The cabinet is maintained under negative pressure and supply air is drawn in through HEPA filters. The exhaust air is treated with either double HEPA filtration or HEPA filtration and incineration. Class III cabinets are safe for work requiring Biosafety Level 1, 2, 3 or 4 containment.